Hazard ID 8 – Injury Associated with Working Near or Operating Wood Chippers

August 1999

DHHS (NIOSH) Publication Number 99-145

Description of Hazard

According to the Bureau of Labor Statistics (BLS) Census of Fatal Occupational Injuries (CFOI), 11 workers lost their lives during 1992 through 1997 while working near mobile wood chippers. In seven of the incidents, the victim was caught by the feed mechanism and pulled through the chipper knives. The victims in four of the incidents were struck by hoods (guards that cover the rotating chipper knives) that separated from the machines after being improperly opened or closed while knives were still rotating.

During 1998, the National Institute for Occupational Safety and Health (NIOSH) received two additional reports of worker deaths from operating wood chippers. These incidents illustrate the two most common causes of fatal injury: being fed through the chipper knives or being struck by the chipper disc hood. The incidents were investigated as part of the NIOSH Fatality Assessment and Control Evaluation (FACE) program.

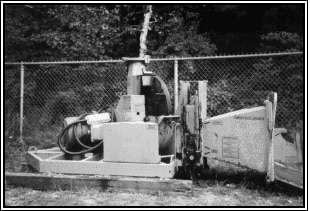

Self-feeding mobile wood chippers commonly used during tree trimming operations consist of a feed mechanism, knives mounted on a rotating chipper disc or drum, and a power plant. Tree branches and trunk sections fed manually into the machine’s infeed hopper are grabbed by the feed mechanism or chipper knives. The chipper disc or drum rotating between 1,000 and 2,000 rpm cuts and propels wood chips through the discharge spout usually into a chip truck. The housing containing the chipper disc or drum is sectioned and includes a removable hood that allows access to machine components for maintenance.

Caught-By Hazard: Workers feeding material into self-feeding wood chippers are at risk of being fed through the chipper knives if they reach or fall into the infeed hopper or become entangled in branches feeding into the machine.

Case Study: A 28-year-old groundsman died after he was caught and pulled into a wood chipper. The victim and two coworkers, a foreman and a climber, were cleaning up limbs after pruning a tulip poplar behind a townhouse. The coworkers were behind the building gathering loose branches while the victim was in front operating the chipper. The coworkers began dragging brush to the chipper. As the climber approached the chipper, he saw the victim’s legs sticking out of the infeed hopper. Investigators concluded that the victim either fell or reached into the infeed hopper while feeding short branches. His hands were caught by the feed mechanism, forcing his head and upper torso into the chipper knives.

Case Study: A 28-year-old groundsman died after he was caught and pulled into a wood chipper. The victim and two coworkers, a foreman and a climber, were cleaning up limbs after pruning a tulip poplar behind a townhouse. The coworkers were behind the building gathering loose branches while the victim was in front operating the chipper. The coworkers began dragging brush to the chipper. As the climber approached the chipper, he saw the victim’s legs sticking out of the infeed hopper. Investigators concluded that the victim either fell or reached into the infeed hopper while feeding short branches. His hands were caught by the feed mechanism, forcing his head and upper torso into the chipper knives.

Struck-By Hazard: Workers are at risk of being struck by unlatched, improperly secured, or damaged or improperly maintained hoods that may be thrown from the wood chipper after contacting the rotating chipper knives.

Case Study: A 46-year-old laborer at a municipal waste-management facility died after he was struck by the flying chipper disc hood from an operating brush chipper. He had been feeding material into a chipper that had been converted to a stationary machine. He had shut off the chipper to remove jammed material, but opened the hood before the chipper disc had stopped completely. The rotating disc hit the hood as he opened it and tore it loose from its hinges. The hood struck the victim in the head and chest. He died the next day without regaining consciousness. Investigation showed that the hood hinges had been damaged, allowing excessive side movement as the hood was swung open.

Recommendations for Prevention

To protect workers from being caught by the chipper feed mechanism, employers should ensure the following:

- All safety devices and controls, such as emergency shut-off devices, are tested and verified to be functioning properly before the chipper is used.

- Workers are trained in safe work procedures, including operating wood chipper safety devices and safety controls. These procedures should be based on the manufacturer’s recommendations for each machine.

- At least two workers are in close contact with each other when operating the chipper.

- Workers wear close-fitting clothing, gloves without cuffs, trousers without cuffs and skid-resistant foot wear. Clothing should be kept tucked in.

- Worker’s hands and feet remain outside the infeed hopper.

- Workers feed brush and limbs into the infeed hopper butt end first.

- Workers feeding material are positioned at the side of the machine to allow quick operation of the emergency shut-off device and minimize risk of entanglement in branches. Because of differences among machines, the manufacturer’s operating manual should be consulted for guidance. Safe feeding of some disc-type chippers requires the worker to be on the right side.

- Workers walk away once the feed mechanism has grabbed the material.

- Workers lay short material on top of longer material that is feeding or use a longer branch to push it through the infeed hopper.

- Workers load small raked-up material such as twigs and leaves directly into the chip truck or in trash cans or bags instead of feeding it into the chipper.

- Workers keep the area around the wood chipper free of tripping hazards.

- Workers wear hard hats, eye protection, and hearing protection.

To protect workers against being struck by flying hoods covering chipper discs or drums, employers should ensure the following:

- Wood chippers are inspected each working day before startup for defects such as broken or missing hood latches and pins or cracked and worn hinges. Broken, damaged, or missing machine components should be repaired or replaced before the machine is placed in service.

- The hood covering the chipper knives is completely closed and latched according to manufacturer’s recommendations before starting the machine.

- Before processing material and unless the manufacturer recommends otherwise, the machine is run at the lowest possible speed while workers listen for noise that might indicate broken or loose machine parts. If unusual noise is detected, the machine should be shut down immediately and evaluated by a competent person. If necessary, the machine should be repaired before being placed in service.

- All internal machine parts have come to a complete stop before the hood covering the chipper disc or drum is opened.

The FACE Program is conducted by NIOSH. The objective of the program is to identify work situations at high risk for fatal injury and formulate and disseminate prevention strategies to those who can intervene in the workplace.

Acknowledgments

The principal contributors to this publication are: Paul H. Moore and Virgil J. Casini, NIOSH Division of Safety Research, Susan Shepherd, Massachusetts Department of Health, and Charles Carson, Texas Worker’s Compensation Commission. Jerome P. Flesch provided technical review, and Vanessa Becks, Susan Kaelin, and Kristina Wasmund provided desktop publishing.

Hazard ID 8 – Injury Associated with Working Near or Operating Wood Chippers [PDF – 220.43 KB]